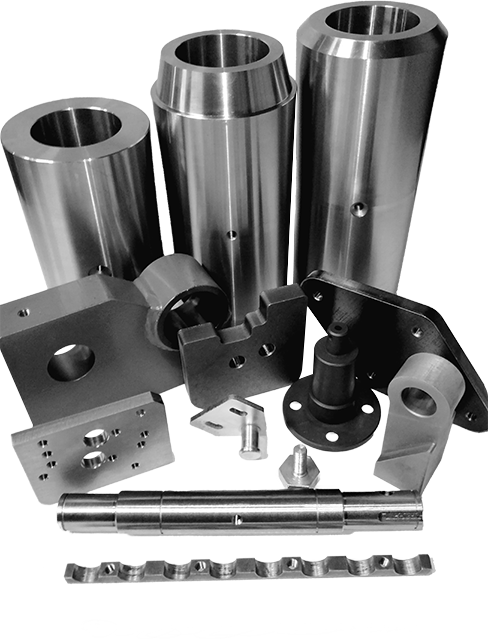

Milling

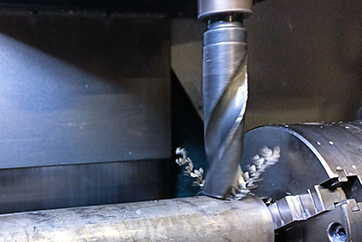

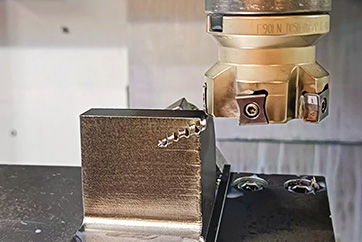

We specialize in the serial production of components and subassemblies using the latest technologies and CNC machines.

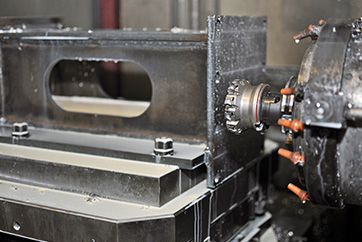

Our machinery park consists of modern numerically controlled machine tools: vertical machining centers and universal vertical-horizontal centers. High efficiency and versatility of machines allows us to produce parts from 4 and 5 sides in one clamping resulting in the production of virtually any detail with high accuracy.

An extensive range of conventional machines complements CNC machine tools and enables the production of one-time parts or prototypes.

Materials

in process:

- carbon steel

- alloy steel

- stainless steel

- aluminum alloys

- brass & bronze

- plastics

Our possibilities:

Our machinery park consists of modern numerically controlled machine tools: vertical and universal machining centers.

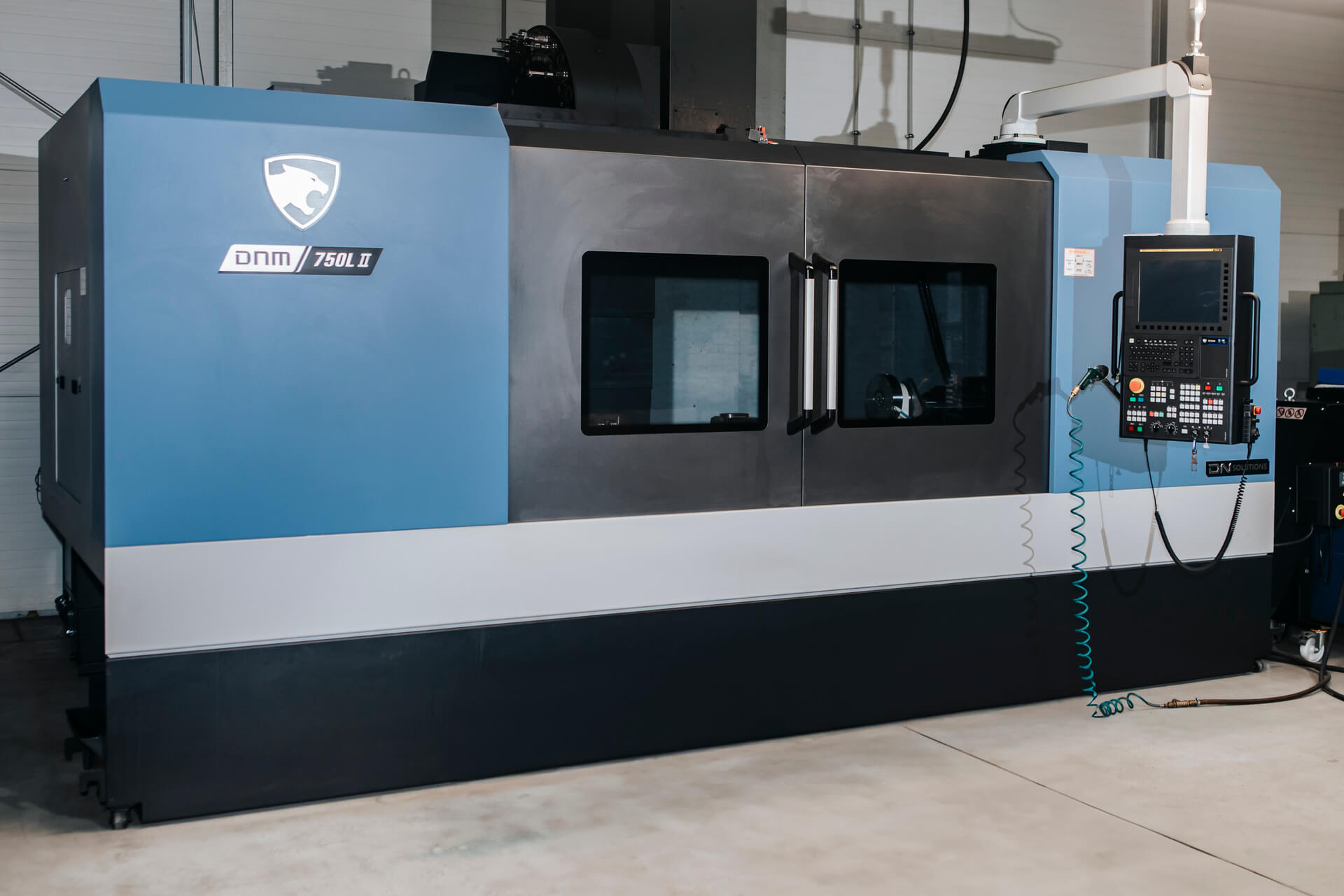

Universal 5 - axis CNC

machining center

Max. dimensions of the rotary table:

1280×800 mm

Max travel:

X 1000 mm

Y 660 mm

Z 800 mm

B 360 x 0.001°

4 - axis

machining center

Table dimensions:

2160 x 760 mm

Max feed

X axis 2160 mm

Y axis 762 mm

Z axis 650 mm

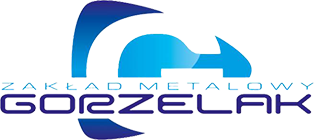

3 - axis CNC vertical

machining center

Max. table dimensions:

2000×500 mm

Max travel:

X 1600 mm

Y 420 mm

Z 480 mm

Conventional milling

Max table size:

1800×320 mm

Conventional drilling

Max table size:

800×500 mm

Max drilling diameter:

50 mm

What makes us stand out

Precision

IT6, IT7

Quality control

Compliance

with ISO standards

Punctuality

Own production

without subcontractors

Large selection of materials

Full

responsibility

for the effect

They trusted us

Do your next project with us!